COB vs SMD LED Display Technology: The Definitive 2025 Comparison Guide

Recommended reading

5 Common Myths About LED Displays: Is Brighter Always Better?

Recommended reading+86 755-33691736inquiry@dicolorled.comNo.13 Huiye Road ,Tangjia Community,Fenghuang Street, Guangming District, Shenzhen,China 518103 Shenzhen Dicolor Intelligent Technology(Dongguang) Co., Ltd Gate No.4-5, Building A-17,...

How Innovative LED Technology Conquers Efficiency and Visual Limits in Touring

Recommended reading+86 755-33691736inquiry@dicolorled.comNo.13 Huiye Road ,Tangjia Community,Fenghuang Street, Guangming District, Shenzhen,China 518103 Shenzhen Dicolor Intelligent Technology(Dongguang) Co., Ltd Gate No.4-5, Building A-17,...

Beyond Price: 3 Overlooked ‘Hidden Values’ When Choosing a High-End Fixed Installation LED Display

Recommended reading+86 755-33691736inquiry@dicolorled.comNo.13 Huiye Road ,Tangjia Community,Fenghuang Street, Guangming District, Shenzhen,China 518103 Shenzhen Dicolor Intelligent Technology(Dongguang) Co., Ltd Gate No.4-5, Building A-17,...

The Ultimate Small Stage Setup Solution: Dicolor UL Series All-in-One Pre-Setting Cart

Recommended reading+86 755-33691736inquiry@dicolorled.comNo.13 Huiye Road ,Tangjia Community,Fenghuang Street, Guangming District, Shenzhen,China 518103 Shenzhen Dicolor Intelligent Technology(Dongguang) Co., Ltd Gate No.4-5, Building A-17,...

Customer Service

+86 755-33691736

inquiry@dicolorled.com

Headquarters Address

No.13 Huiye Road ,Tangjia Community,Fenghuang Street, Guangming District, Shenzhen,China 518103

Shenzhen Dicolor Intelligent Technology(Dongguang) Co., Ltd Gate No.4-5, Building A-17, No.780 Xiecao Road , Xiegang Town, Dongguan, Guangdong, China

COB vs SMD LED Display Technology: The Definitive 2025 Comparison Guide

Introduction: Facing the COB vs SMD Decision?

Selecting the right LED technology is a critical decision for integrators, AV managers, and project planners. While SMD has been the industry standard for over a decade, COB (Chip on Board) technology is rapidly gaining ground as the preferred choice for next-generation applications. But what truly sets them apart? This definitive guide cuts through the technical jargon to provide a clear, actionable comparison between COB and SMD displays, helping you make an informed investment for your specific needs.

SMD and COB Defined: Understanding the Core Technologies

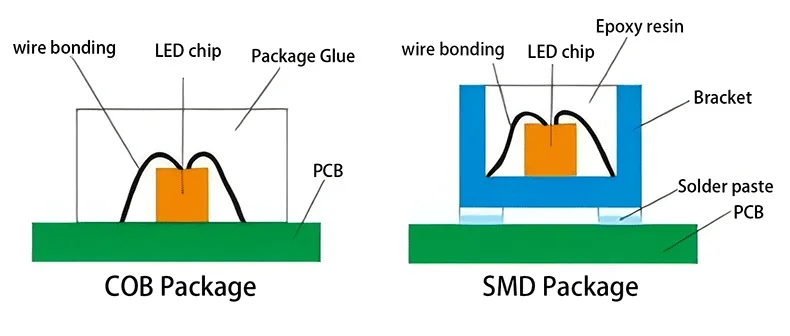

SMD (Surface-Mounted Device): The Established Workhorse

In SMD technology, individual LED chips are first packaged into discrete, lead-mounted components (often called “lamps” or “LEDs”). These components are then soldered onto the surface of a PCB using highly automated SMT (Surface-Mount Technology) pick-and-place machines. This process is mature, scalable, and has been the backbone of the LED display industry.

COB (Chip on Board): The Integrated Future

COB technology takes a more integrated approach. Multiple bare LED chips are directly mounted and bonded onto the PCB substrate. The entire array of chips is then encapsulated under a protective, continuous layer of epoxy resin, forming a single, robust module. This advanced process paves the way for superior performance in fine-pitch LED displays.

Manufacturing Process: A Side-by-Side Look

SMD Technology: Multi-step: Lamp Packaging → SMT Placement → Reflow Soldering → Cleaning

COB Technology: Integrated: Direct Die Attachment → Epoxy Resin Molding → Curing

Head-to-Head: COB vs SMD Performance Comparison

| Feature | SMD Display | COB Display | Our Verdict |

|---|---|---|---|

| Durability & Reliability | Prone to dead pixels, physical damage, and lamp fallout. | Exceptionally robust. No risk of lamp fallout. Highly resistant to impact. | ✔️ COB Wins |

| Environmental Protection | Gaps between lamps can trap dust, moisture. Lower IP rating. | Seamless, flat surface. Typically achieves an IP54 protection rating. | ✔️ COB Wins |

| Fine-Pitch Capability | Difficult and expensive below P1.0. | Easier, more reliable production of ultra-fine pitches (P0.9 and below). | ✔️ COB Wins |

| Image Quality | Mature technology with good color performance. | Higher Contrast, Better Uniformity, Wider Viewing Angle (170°). | ✔️ COB Wins |

| Thermal Management | Less efficient heat dissipation. | Superior heat dissipation for longer lifespan. | ✔️ COB Wins |

| Upfront Cost | Mature supply chain keeps initial costs lower. | Higher technology and material costs. | ✔️ SMD Wins |

| Maintenance & Repair | Individual lamps can be replaced on-site. | Failed chip requires module to be sent back to factory. | ✔️ SMD Wins |

Market Outlook: The Shift Towards COB is Accelerating

The demand for higher-fidelity visual experiences is driving adoption of COB technology. As manufacturing scales and costs decrease throughout 2025, COB is moving into the mainstream. We expect significant growth in COB-based P1.2 and P0.9 products, fueling expansion in virtual production studios, executive boardrooms, and command and control centers.

Real-World Innovation: The Dicolor HA-C Series COB Display

Leading manufacturers are answering the call with advanced COB solutions. The Dicolor HA-C Series exemplifies this innovation:

- Unmatched Protection: Withstands 100kg/cm² of pressure, eliminating shipping damage.

- Exceptional Stability: Superior resistance to ESD, corrosion, and oxidation.

- Broadcast-Grade Color: 281 trillion color shades, anti-glare treatment, 170° viewing angle.

- Advanced Cooling: Energy-efficient common cathode drive and honeycomb backplate.

COB or SMD? Making the Right Choice for Your Project

Your choice ultimately depends on your project’s specific requirements and budget.

Choose SMD if: Your budget is a primary constraint, you require a pitch above P1.2, and on-site repairs are a critical necessity.

Choose COB if: You require the best possible image quality, superior durability, ultra-fine pitch, and are focused on long-term value through reduced maintenance.

For mission-critical applications, COB technology represents the clear and future-proof choice.

Ready to Specify the Right Technology for Your Next Project?

Contact our technical specialists today for a personalized consultation and competitive quote.

Dicolor is a global provider of LED displays. We show premium technology with cutting-edge technology and advanced innovations, providing LED display products, solutions,and services worldwide for rental stage events, ads billboards, commercial display, etc.